Seamed Acrylic Panels for Oversized Glazing, Wall Cases, and Vitrines

Seaming is bonding two or more acrylic sheets edge-to-edge to create one larger sheet, then finishing it so it can be used like a single oversized panel. This is how large-format acrylic panels are made beyond the maximum sizes produced by sheet manufacturers. We seam acrylic for custom framing and gallery glazing, architectural installations, wall cases, and vitrines.

Quick Seamed Acrylic Sheet Specs

Commonly used materials: Tru Vue Optium Museum Acrylic and other acrylic sheets (based on clarity, thickness, and application)

Also used for: Wall cases, vitrines, and oversized display glazing panels

Typical deliverables: Seamed oversized panels, seam refinement, surface protection, crating, and delivery planning

Seam options: Single seam, double seam, multi-panel assemblies (seam placement by sightlines and design intent)

Post-process options: Trimming, edge finishing, or machining when feasible based on final panel size

For fastest quoting: Finished size, thickness, seam preference (or sightlines), and shipping/handling constraints

Fastest response: sales@archplastics.com. Email files for quick feasibility feedback.

Our Seaming Process

We have one of the largest in-stock inventories of Tru Vue Optium Museum Acrylic in the San Francisco Bay Area. This allows our seamed panels to be completed quickly with very short lead times, usually a week or less.

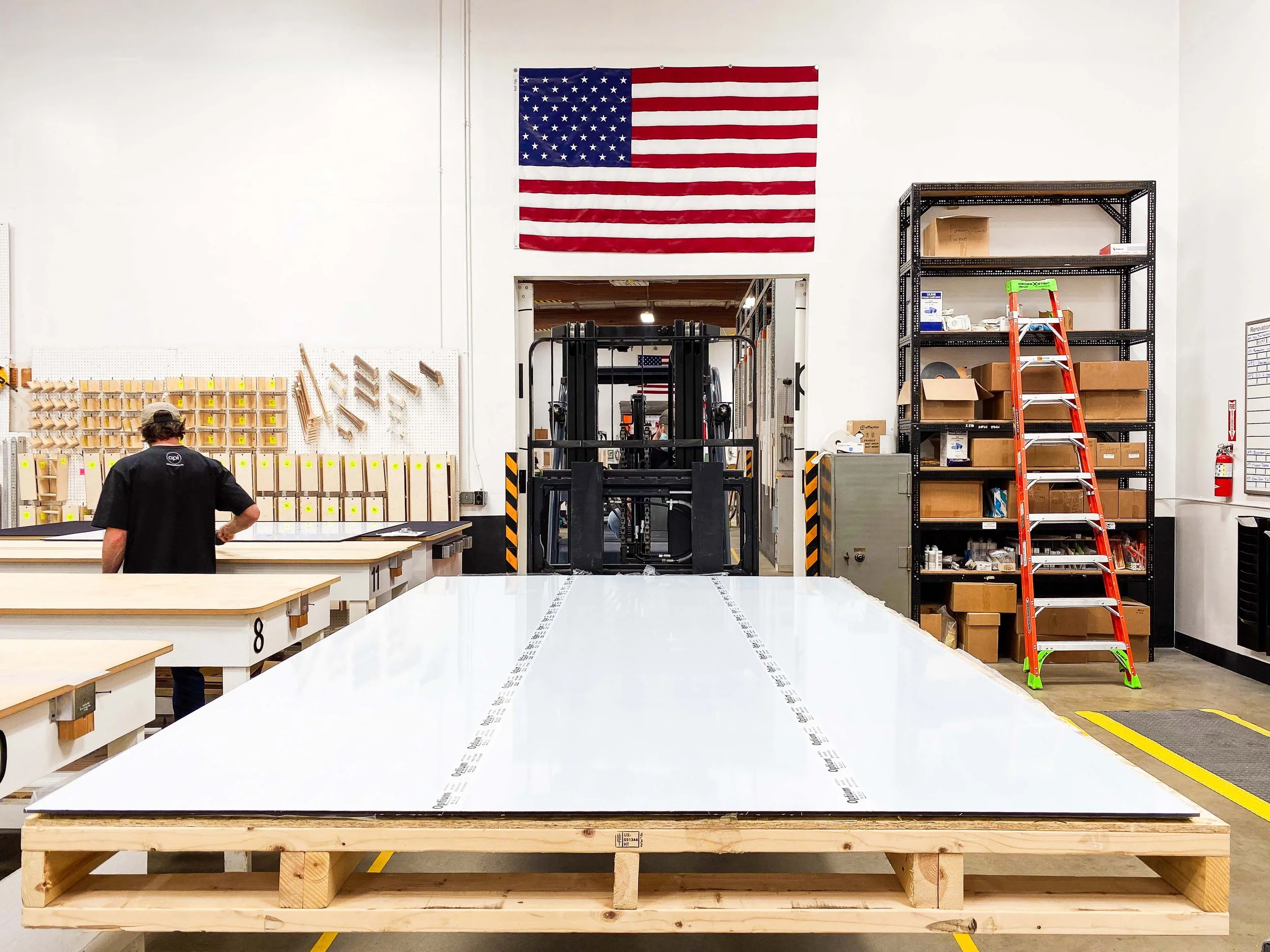

First Optium Museum Acrylic panel for a multi-seam panel assembly.

Multi-seamed Optium Museum Acrylic panel ready for loading into a custom oversized crate.

Our fabricators loading a double seamed Optium Museum Acrylic panel onto our box truck for delivery at our Petaluma, CA facility.

Crane lifting the double seamed Optium Museum Acrylic panel into a private San Francisco, CA residence.

Services available for seamed acrylic sheets

Seamed Oversized Acrylic Panels

We seam acrylic sheets edge-to-edge to create oversized panels beyond manufacturer sheet sizes. Seam layout is planned for sightlines, framing, and installation, and we prioritize clean seams, careful handling, and surface protection so the finished panel arrives ready to use.

Best for:

Oversized glazing and large-format panels beyond manufacturer sheet sizes, including framing, galleries, wall cases, vitrines, and architectural projects.

You receive:

A seamed panel built to your finished size requirements

Seam placement guidance based on sightlines, lighting, and mounting method

A finished oversized panel with protection and packing planned around shipping and installation

Seamed Tru Vue Optium Museum Acrylic

Tru Vue Optium Museum Acrylic is a common choice for large-format conservation glazing and presentation-critical framing. We regularly work with frame shops and galleries supporting oversized artwork, where seam placement, surface protection, and safe delivery matter as much as the final size.

Best for:

Oversized conservation glazing for framed artwork where seam quality and surface protection are critical.

You receive:

A seamed Optium Museum Acrylic panel built for your finished frame size

Seam strategy aligned to viewing distance, lighting, and sightlines

Surface protection and crating strategy to reduce handling risk

Post-Processing for Oversized Seamed Panels

Most seamed panels are too large to fit on CNC equipment after seaming. When a project requires trimming, edge work, or machining, we plan the approach around final panel size and handling constraints. In some cases we can machine components before seaming, or complete limited post-processing when the finished panel size allows.

Best for:

Projects that need trimming, edge work, or features and are within equipment and handling limits.

You receive:

A realistic plan for what can be processed after seaming versus before seaming

Reduced risk approach for oversized panels and tight presentation requirements

Clear expectations on feasibility, handling, and lead time

Oversized Glazing for Framers and Galleries

We seam large-format glazing for frame shops and galleries that represent artists with oversized work. The goal is simple: glazing that fits the frame, reads clean under gallery lighting, and arrives protected so installation is straightforward.

Best for:

Frame shops and galleries glazing oversized artwork beyond standard manufacturer sheet sizes.

You receive:

Oversized seamed Optium Museum Acrylic glazing cut to your frame-ready dimensions

Seam placement guidance based on the artwork, matting, and viewing conditions

Protected packaging and delivery planning to reduce damage risk before install

Wall Cases and Vitrines Built from Seamed Acrylic Panels

Wall cases and vitrines often require glazing panels beyond standard sheet sizes, with seams positioned for clean sightlines and close viewing. We seam oversized acrylic panels for display projects, with careful handling, surface protection, and packaging so panels arrive ready for case fabrication and installation.

Best for:

Museum wall cases and vitrines that require oversized glazing panels beyond standard sheet sizes.

You receive:

Seamed oversized acrylic panels sized and prepped for case fabrication

Panels sized and prepared to match your wall case or vitrine build requirements, with finishing coordinated to the project

Packaging and delivery planning to protect seams and surfaces through install

Packaging, Crating, and Delivery Planning

Oversized acrylic fails most often during handling and shipping, not fabrication. We design protection, crating, and delivery strategy around surface quality and seam integrity so panels arrive install-ready and on schedule.

Best for:

Large seamed panels where delivery method, access, and protection requirements drive risk.

You receive:

Protective packaging and crating strategy tailored to panel size and finish

Delivery planning aligned with jobsite access and install sequence

Reduced risk of surface damage, seam stress, and transit surprises

Quote factors for seamed acrylic panels

These variables drive cost, lead time, and feasibility.

Finished panel size and thickness

Quantity and whether the order will repeat (one-off vs production)

Number of seams and total seam length

Seam location requirements (fixed location, preferred location, or we propose based on sightlines)

Visual expectations (viewing distance, lighting conditions, and how noticeable a seam can be in your application)

Surface requirements (protective film, masking, and handling sensitivity)

Any trimming or processing requirements, and whether the final panel size allows it

Packaging and shipping method (local delivery vs freight, crating requirements, jobsite access)

Timeline and any hard deadlines

Installation constraints (frame type, captured edges, standoffs, wall case/vitrine design, access limitations)

What to send for a fast quote

Send what you have. If the details below are included, we can quote faster and reduce back-and-forth.

Finished size (length × width) and thickness

Quantity

Material requirement (Tru Vue Optium Museum Acrylic or other acrylic sheet)

Seam preference (location if you have one, or tell us what you are trying to achieve visually)

Viewing conditions (viewing distance, lighting type, and whether the seam is acceptable in the field of view)

How it installs (frame, captured edges, standoffs, wall case/vitrine, etc.)

Any trimming or processing requirements (if applicable), plus drawings if you have them

Ship-to address and delivery constraints (dock, stairs, appointment delivery, etc.)

Target lead time

FAQs

What is seaming?

Seaming is bonding two or more acrylic sheets edge-to-edge to create one larger sheet, then finishing it so it can be used like a single oversized panel.

How big of a panel can you seam?

We seam oversized panels beyond standard sheet sizes. The practical limit depends on thickness, handling risk, visual requirements, packaging, shipping method, and installation constraints. Send your target size and we’ll confirm feasibility quickly.

Can the seam be invisible?

A seam can be very clean, but “invisible” depends on thickness, lighting, viewing distance, and seam placement. If seam appearance is critical, share the viewing conditions and we will recommend a seam strategy that matches your expectations.

Where should the seam be located?

It depends on sightlines and how the panel will be framed or installed. If you have a preferred seam location, we can work to it. If not, tell us what matters visually and we’ll recommend placement.

Should the panel be processed before or after seaming?

It depends on final panel size and the features required. Many oversized seamed panels are too large to process on equipment after seaming, so any processing may need to be handled before seaming or through limited post-processing when feasible. Send your requirements and we’ll recommend the safest approach.

Do you only seam Tru Vue Optium Museum Acrylic?

No. Tru Vue Optium Museum Acrylic is a common material for large-format conservation glazing, but we also seam other acrylic sheets for large display glazing, protective panels, and architectural applications.

Do you work with frame shops and galleries?

Yes. We regularly support frame shops and galleries that represent artists with oversized work, where seam placement, surface protection, and safe delivery are important for a clean install.

Can you seam panels for wall cases and vitrines?

Yes. We seam oversized display glazing panels for wall cases and vitrines, and we plan handling, protection, and packaging so panels arrive ready for case fabrication or installation.

How do you ship oversized seamed panels?

Oversized acrylic is most vulnerable during handling and transit. We use surface protection and crating strategies tailored to panel size, finish requirements, and delivery method. Share your ship-to location and access constraints and we’ll recommend the safest approach.