Plastic Thermoforming for Repeatable Fit, Clean Geometry, and Premium Finish

Thermoforming reshapes flat plastic sheet into curved or compound-formed parts using controlled heat and purpose-built molds. When it’s done right, you get consistent geometry, predictable fit, and a finished look that doesn’t read as “formed in a hurry.” Architectural Plastics thermoforms parts for clients who need repeatable results, not guesswork.

We build molds in-house and form parts with process control designed to support both prototypes and production runs. We also plan trimming and downstream machining up front so the formed part fits the real assembly, not just the mold. If you’re trying to avoid warping, inconsistent pull, stress marks, or parts that don’t register correctly after trimming, this is where to start.

If you have drawings, dimensions, or an existing part to match, send what you have. We’ll review feasibility and recommend the right forming approach before work begins.

Thermoforming Options:

Large-format thermoforming for parts that must stay consistent and install cleanly.

Repeatable line bending for simple curves.

In-house mold building for controlled geometry and repeatability.

Prototypes through production runs with unit-to-unit matching.

Trimming and secondary machining planned for accurate fit after forming.

Finish expectations set up front for high-visibility parts.

Thermoforming Process Video

This short video shows our thermoforming workflow from start to finish: controlled heating in our thermoforming oven, forming over a fixture, and handling the part through cooling and release. It’s the fastest way to understand what we can form, how we control geometry, and what “repeatable” looks like before you send files.

Thermoforming results depend on the forming approach, the form or mold design, the heating profile, and how the part is supported and cooled. CNC trimming or secondary machining is available to hit final interfaces and formed sections can be bonded into larger assemblies.

Thermoforming Examples

Examples of formed parts and assemblies where geometry, fit, and finish quality matter. Thermoforming is often paired with CNC trimming and secondary machining to hit final dimensions and interfaces.

Large-format plastic thermoforming oven used to heat sheet material evenly before forming.

Heated acrylic sheet removed from the thermoforming oven and handled with protective gloves before forming.

Thermoforming mold and fixture setup used to control curvature and hold alignment during cooling.

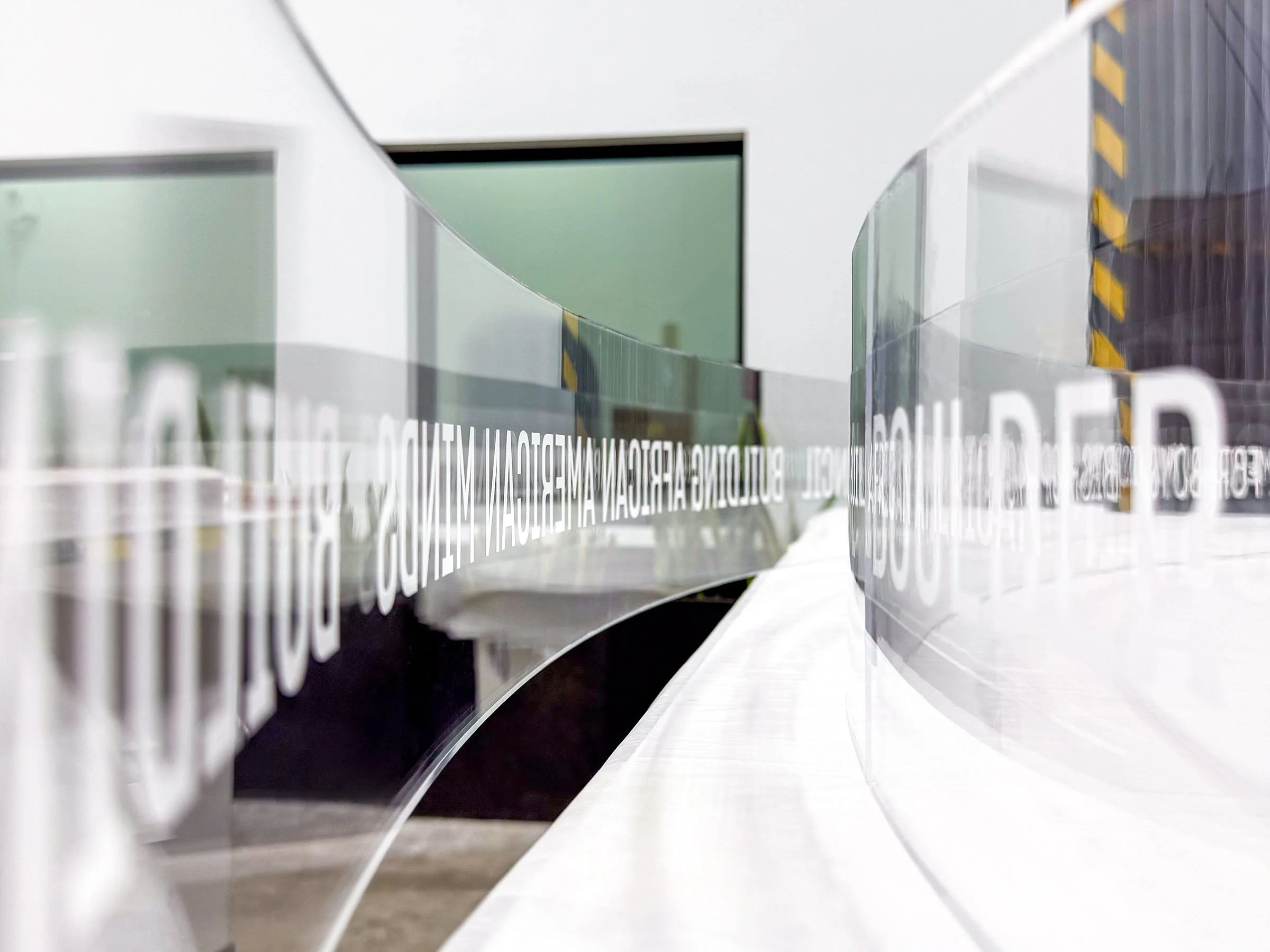

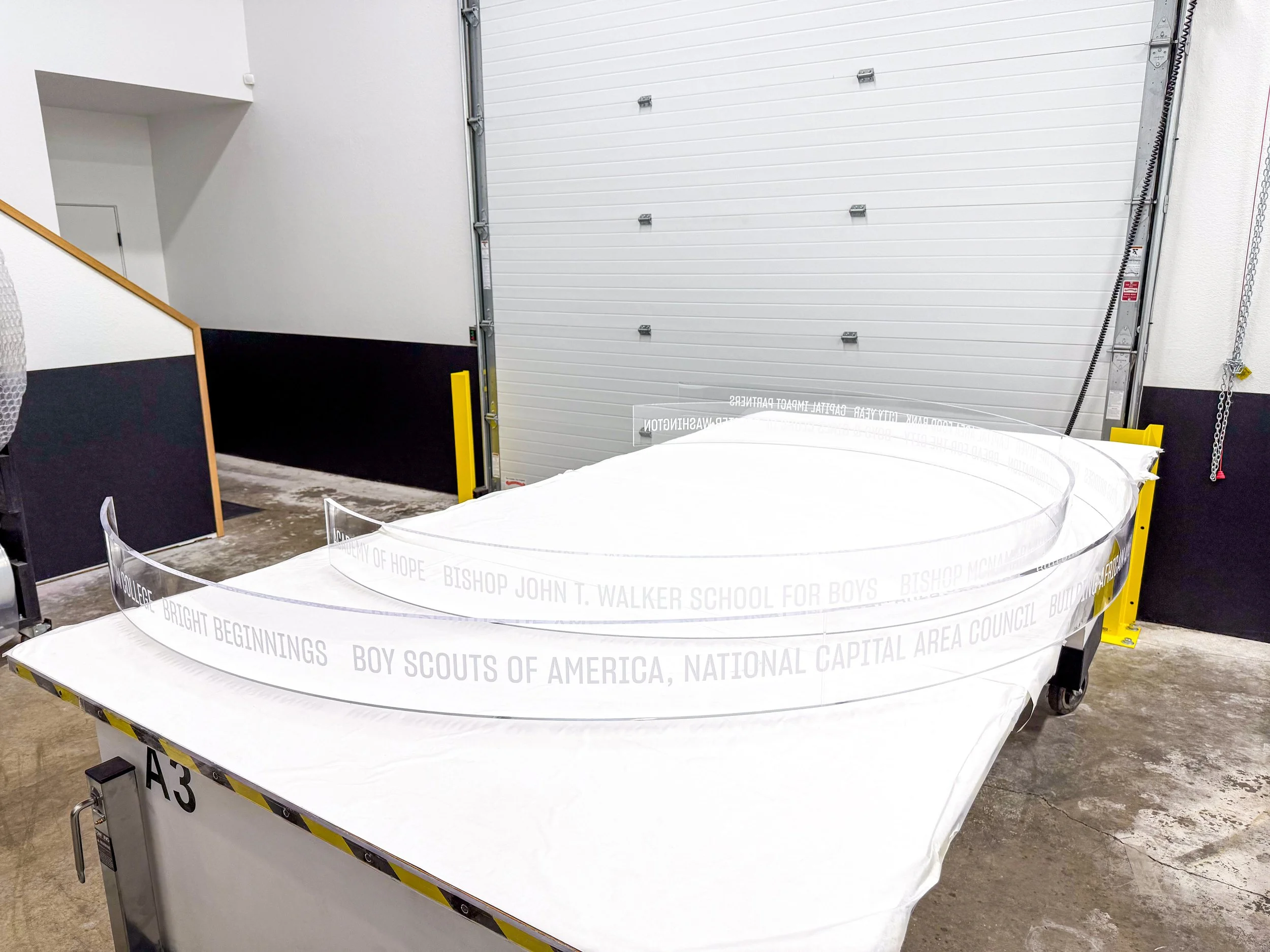

Large curved acrylic panels produced by thermoforming for consistent geometry and clean visual presentation.

Thermoforming Services and Processes

Formed Panels and Covers

Thermoformed panels and covers are ideal when you need lightweight stiffness, smooth curvature, or protective geometry that would be inefficient to machine from solid. We form parts with consistent pull and planned trim strategy so the final perimeter and interfaces register correctly.

Best For:

Machine covers, protective shields, equipment panels, formed guards, architectural panels.

You receive:

Controlled forming for consistent geometry.

Trim planning for accurate final fit.

Finish expectations set up front for visible surfaces.

Complex Curves and Compound Geometry

Compound forms raise the difficulty level fast. We thermoform parts where curve consistency and symmetry matter, using mold strategy and process control to avoid distortion, thinning problems, and inconsistent pull from part to part.

Best For:

Compound curves, wrapped corners, deep draws, formed housings, curved enclosures.

You receive:

Mold strategy aligned with geometry and material behavior.

Process control to reduce warping and pull variation.

Repeatable parts that match the assembly intent.

Large Format Thermoforming

Large parts bring handling risk and distortion risk. We thermoform large-format panels and components while controlling support, cooling, and handling so parts stay stable and usable after forming and trimming.

Best For:

Large panels, oversized covers, architectural scale parts, wide formed components.

You receive:

Large-part handling strategy to protect geometry and surfaces.

Controlled cooling and staging to reduce distortion.

Formed parts designed to ship and install cleanly.

Thermoforming With CNC Trimming and Secondary Machining

Most formed parts need accurate interfaces after forming. We pair thermoforming with CNC trimming, edge details, cutouts, hole patterns, and secondary machining so formed parts fit the real assembly and align with hardware, fasteners, and mating parts.

Best For:

Formed parts with cutouts, hole patterns, alignment features, and interface-critical geometry.

You receive:

CNC trimming planned as part of the forming strategy.

Accurate cutouts, drilling, and patterns after forming.

Better fit and alignment with fewer field modifications.

Prototypes and First-Article Validation

Thermoforming is sensitive to geometry, material, and process settings. For new parts, we can prototype or run a first-article approach to validate pull behavior, trim, fit, and appearance before committing to production quantities.

Best For:

New product development, first-time formed parts, high-risk geometry, appearance-critical parts.

You receive:

Early validation of geometry, fit, and appearance.

Recommendations that reduce risk before scaling quantity.

A clearer path to repeatable production results.

Production Runs

For repeat production, consistency is everything. We build thermoforming runs around stable molds, controlled heating, repeatable handling, and defined trim strategy so parts match from unit to unit.

Best For:

Repeat orders, multi-unit builds, standardized formed components, production programs.

You receive:

Unit-to-unit consistency based on controlled setups.

Repeatable trim and interface alignment.

Predictable throughput and delivery planning.

Materials We Thermoform

We thermoform plastics based on performance requirements such as clarity, impact resistance, temperature behavior, and finish expectations. Acrylic and polycarbonate are the most common for high-visibility work, but we also form other sheet plastics depending on the application.

Common Thermoforming Materials:

Acrylic, PMMA (clear, frosted, and color acrylic)

Polycarbonate (impact-resistant formed parts)

ABS (durable formed housings and covers)

Type 1 PVC (formed panels and guards where appropriate)

HDPE (functional parts for industrial uses)

Other Sheet Plastics (application dependent)

What Drives Thermoforming Pricing

Thermoforming cost is driven by a combination of tooling, part geometry, material, finishing, and quantity. The biggest variable is usually the form or mold required to produce the part consistently.

Key pricing drivers:

Form or mold cost (one-time tooling to control geometry and repeatability)

Part size and depth of draw (larger parts and deeper forms require more control)

Material type and thickness (affects heating time, stability, and trim strategy)

Quantity (prototype vs production run changes the best approach)

Trim requirements (final perimeter, cutouts, holes, post-form machining)

Finish expectations (show surfaces, optical clarity, stress mark sensitivity)

Handling and packaging requirements (large parts often need special protection)

How to Reduce Cost Without Compromising Function:

If cost is a concern, we can value engineer the build by adjusting material, thickness, finish targets, or tooling strategy while still meeting functional requirements. For higher volumes, the right tooling and repeatable trim strategy typically lowers unit cost and reduces variation.

What We Need to Quote Thermoforming

Send drawings, CAD, or a sketch with key dimensions. If you have an existing part to match, send photos and measurements or ship the part for review.

Include:

Material preference (or performance requirement if you’re unsure)

Thickness

Overall part dimensions, depth, radii, and draft (even approximate is helpful)

Quantity (prototype, short run, or production run)

Trim requirements (final perimeter, cutouts, hole patterns)

Finish expectations (show surfaces vs non-visible surfaces)

Ship-to city/state and timeline

FAQs

What Is the Maximum Part Size You Can Thermoform?

Our thermoforming oven can form parts up to 51″ × 121″. If your assembly needs to be larger, we can form multiple sections and bond them into a larger finished build when the application allows.

Do You Build Forms and Molds In-House?

Yes. We build forms and fixtures in-house and select the approach based on geometry, material, and repeatability requirements.

Can You Hold Tight Tolerances on Thermoformed Parts?

Thermoformed parts typically require CNC trimming or secondary machining to hit final interfaces. We plan that into the workflow so parts fit correctly after forming.

Can You Thermoform Clear Acrylic Without Haze or Distortion?

Yes, within material-appropriate limits. Appearance depends on geometry, thickness, heating consistency, and forming method. We set finish expectations up front and plan around show surfaces.

Can You Thermoform and Then Glue Parts Into Larger Assemblies?

Yes. We can bond thermoformed parts together to create larger assemblies or to integrate formed components into a finished build.

Do You Do Prototypes and Production Runs?

Yes. We support one-off prototypes, first-article validation, short runs, and repeat production runs with unit-to-unit consistency.

What Causes Warping or Inconsistent Pull?

Warping and pull variation are driven by geometry, thickness, heating consistency, form design, and cooling/handling. We plan around these factors up front to reduce risk.

If you have drawings, dimensions, or an existing part to match, send what you have. We’ll review feasibility and recommend the right forming approach before work begins.