Design for Manufacturing and CAD Services for Buildable, Production-Ready Fabrication

Architectural Plastics provides design-for-manufacturing support that bridges concept development, engineering, prototyping, and fabrication. We work with architects, museums, artists, builders, and brands who need designs that do not just look good, but can actually be built, installed, and repeated. Our process is fabrication-aware from the start. We reduce risk, cost overruns, and production delays by solving problems early, before materials are ordered or timelines are locked.

In-house design and fabrication in Petaluma, CA, built around real process control for visually critical, high-precision work.

Already have drawings? Email them to us directly for the fastest feedback: sales@archplastics.com

Design-for-Manufacturing Projects: CAD Development, Prototyping, and Fabrication

We support projects where material behavior, finish quality, and assembly sequencing matter. That includes display cases, museum vitrines, architectural systems, wine storage, retail displays, and multi-material assemblies.

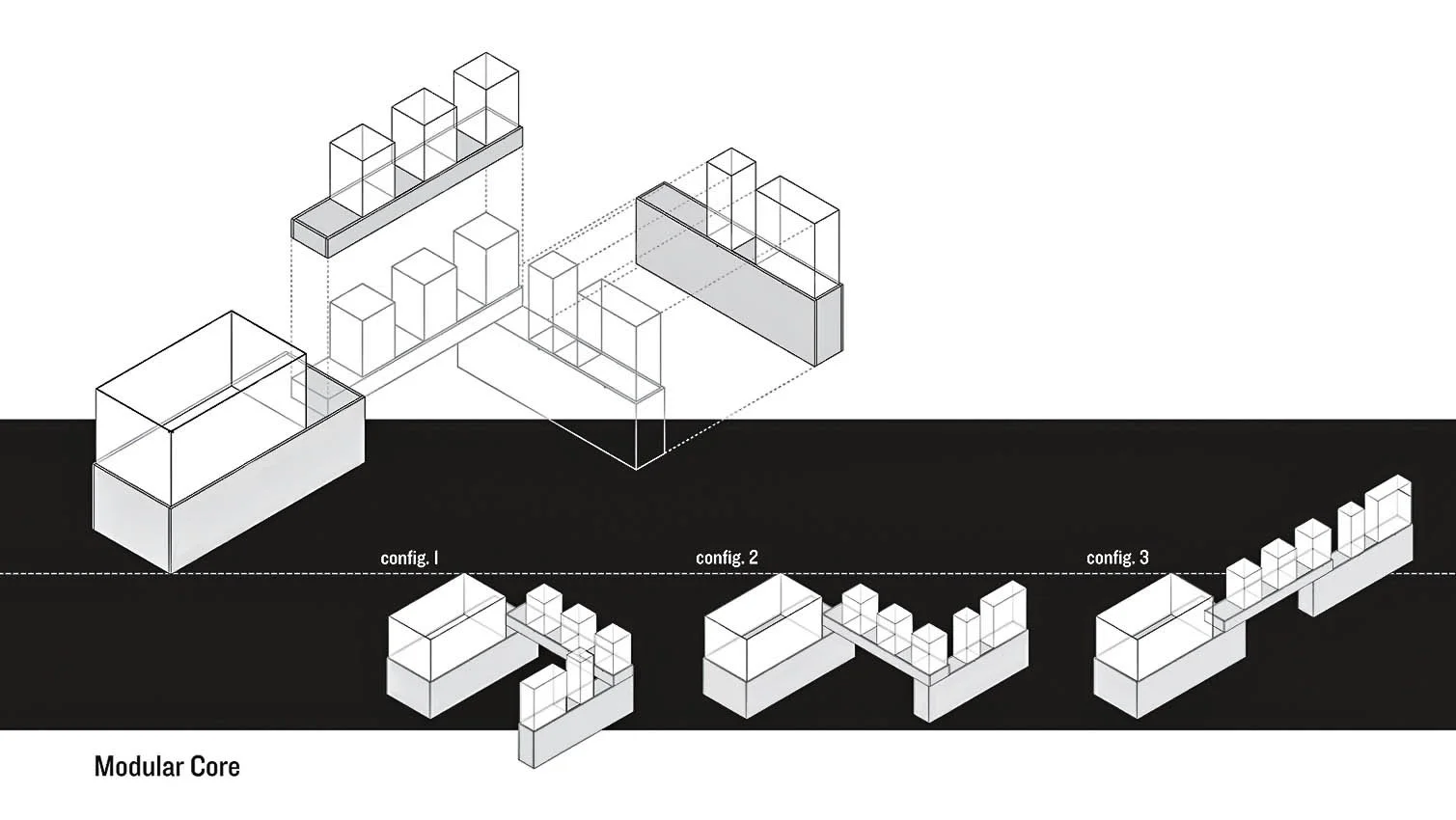

Conceptual design for a metal and glass enclosed two-story wine cellar.

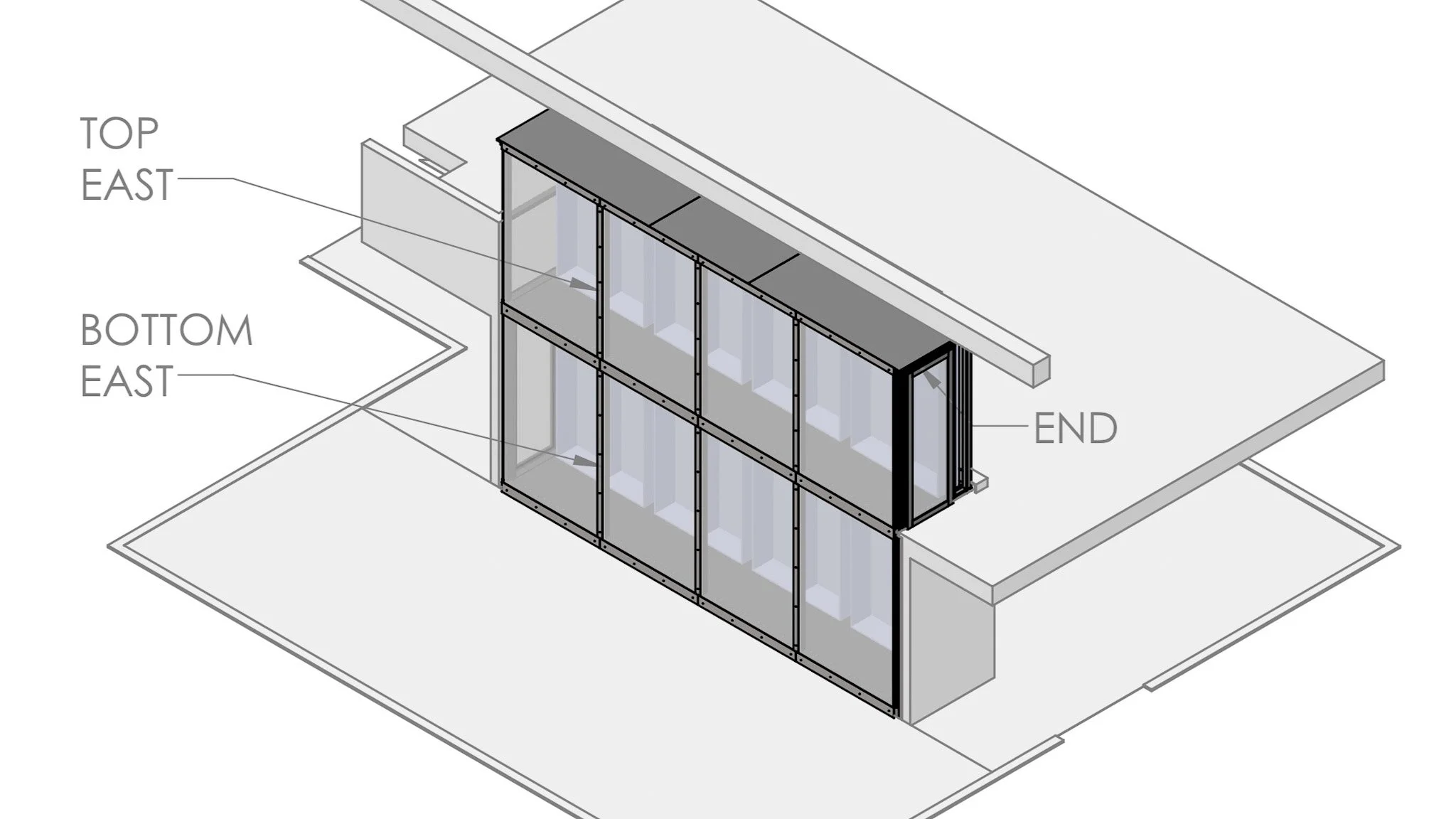

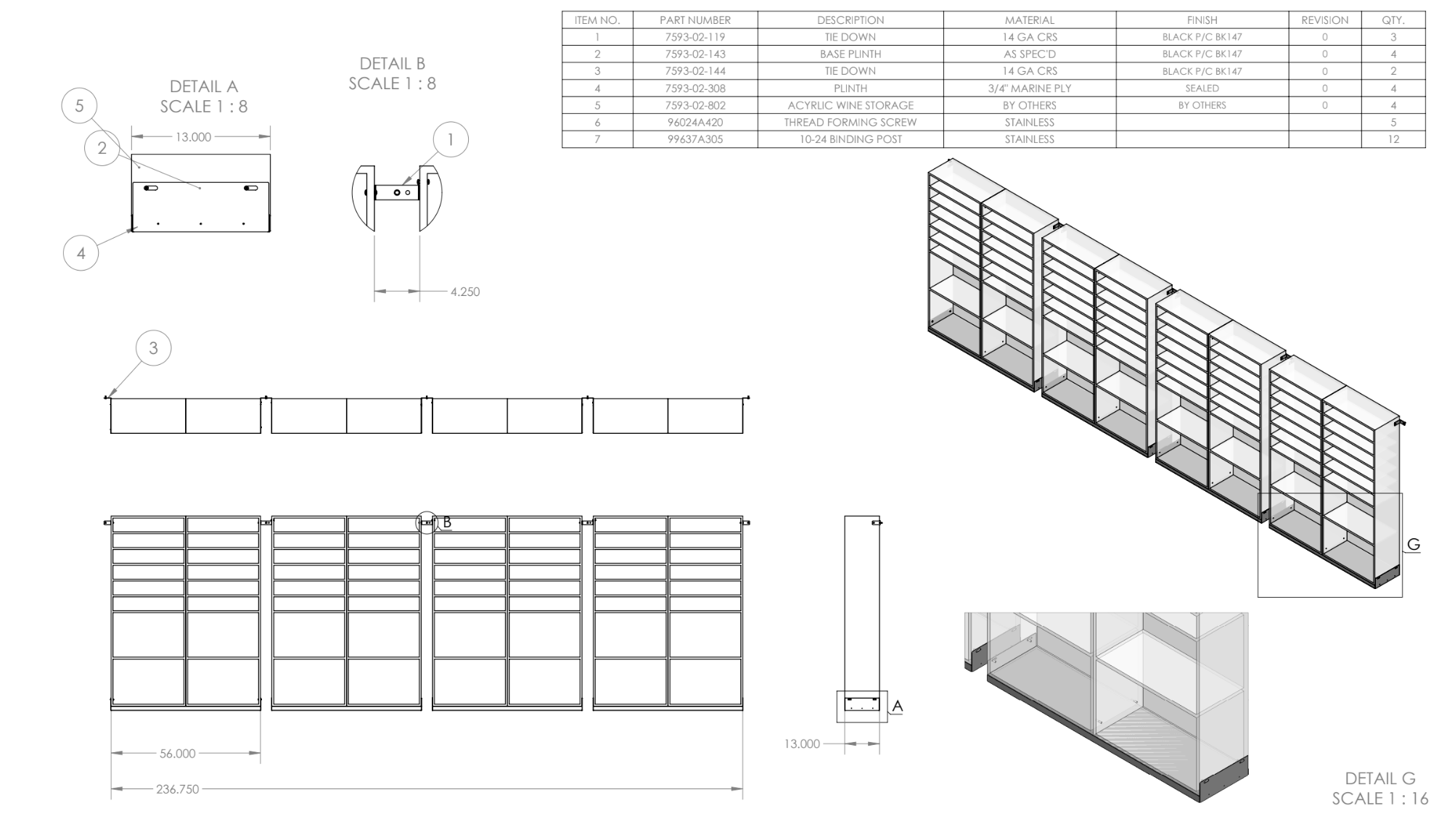

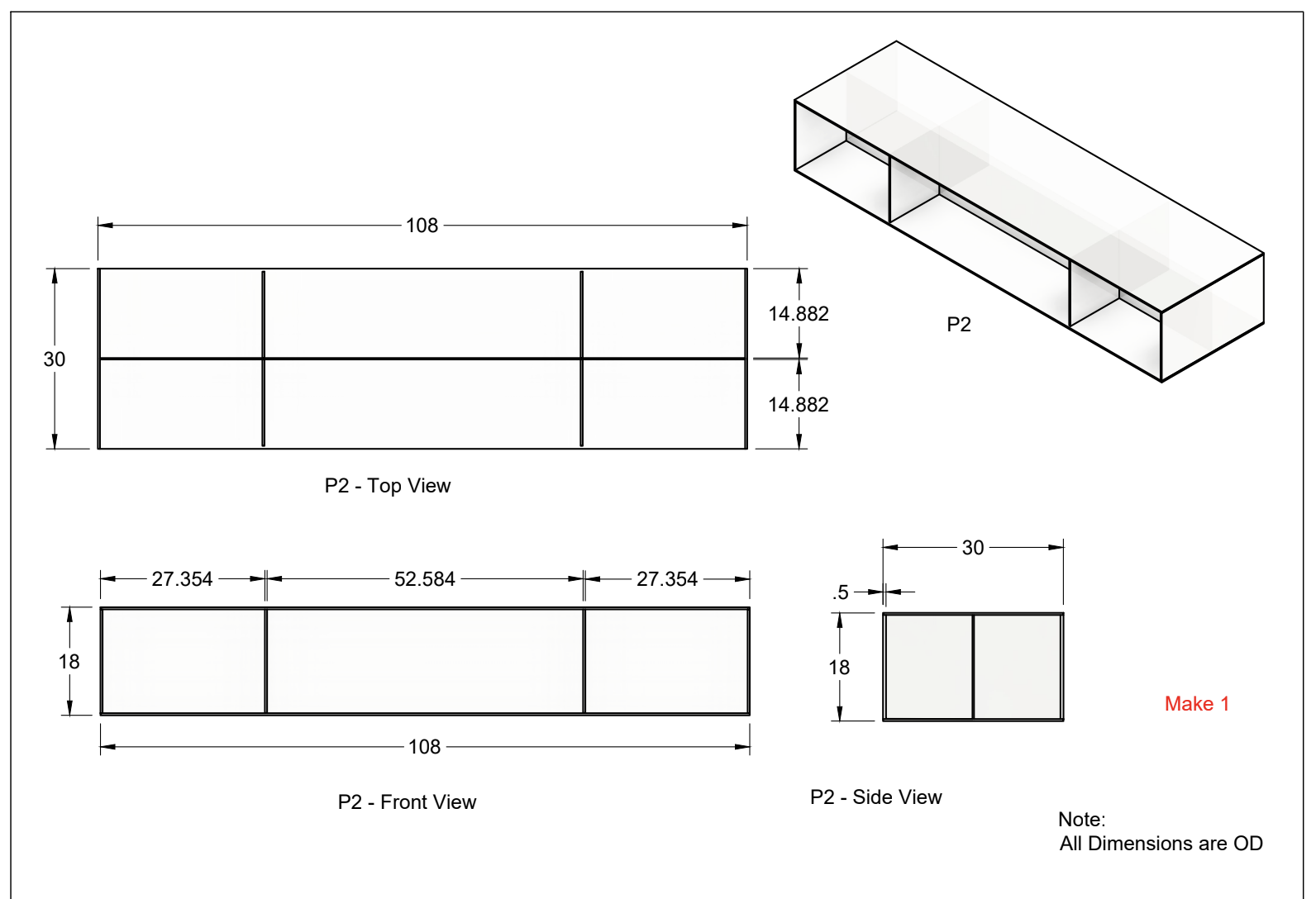

Architectural fabrication CAD drawing illustrating design-for-manufacturing, module layout, dimensions, and material specifications for a custom wine storage installation.

Fabrication crew assembling acrylic wine racks.

Completed two-story acrylic wine cellar with LED lighting in a metal and glass enclosure.

How Clients Typically Work With Our Design Team

Choose the level of support that fits your project stage. We can assist you from concept all the way through to a buildable, aesthetic design that holds up in production and installs cleanly.

Concept Feasibility and Design Review

Best for:

Early-stage ideas, budget reality checks, technical risk reduction. We evaluate concepts for buildability, material behavior, tolerances, finishes, installation constraints, and cost drivers before you commit to production.

You receive:

Practical feasibility feedback

Early identification of risk areas

Clear next-step recommendations

Material recommendations

Production-Ready Shop Drawings

Best for:

Architects, designers, and project teams that need buildable documentation. We produce accurate CAD models and shop drawings aligned with real fabrication processes, tolerances, and assembly sequencing—so nothing is left to interpretation on the shop floor.

You receive:

Fabrication-ready CAD geometry

Shop drawings coordinated with materials and hardware

Revision control and design coordination

Prototyping and Fabrication Support

Best for:

Premium finishes, tight tolerances, or repeat production runs. When finish quality, fit, or user interaction matters, prototyping validates the design before full production. We support projects from prototype through fabrication and delivery.

You receive:

Prototype planning and execution

Finish and assembly validation

Direct handoff to our fabrication department

Fast in-house CNC milling

Concept-to-Installation Exhibit Fabrication Example: Modular Display Cases and Pedestals

Concept rendering of a modular display system showing case, pedestal, and layout proportions before fabrication.

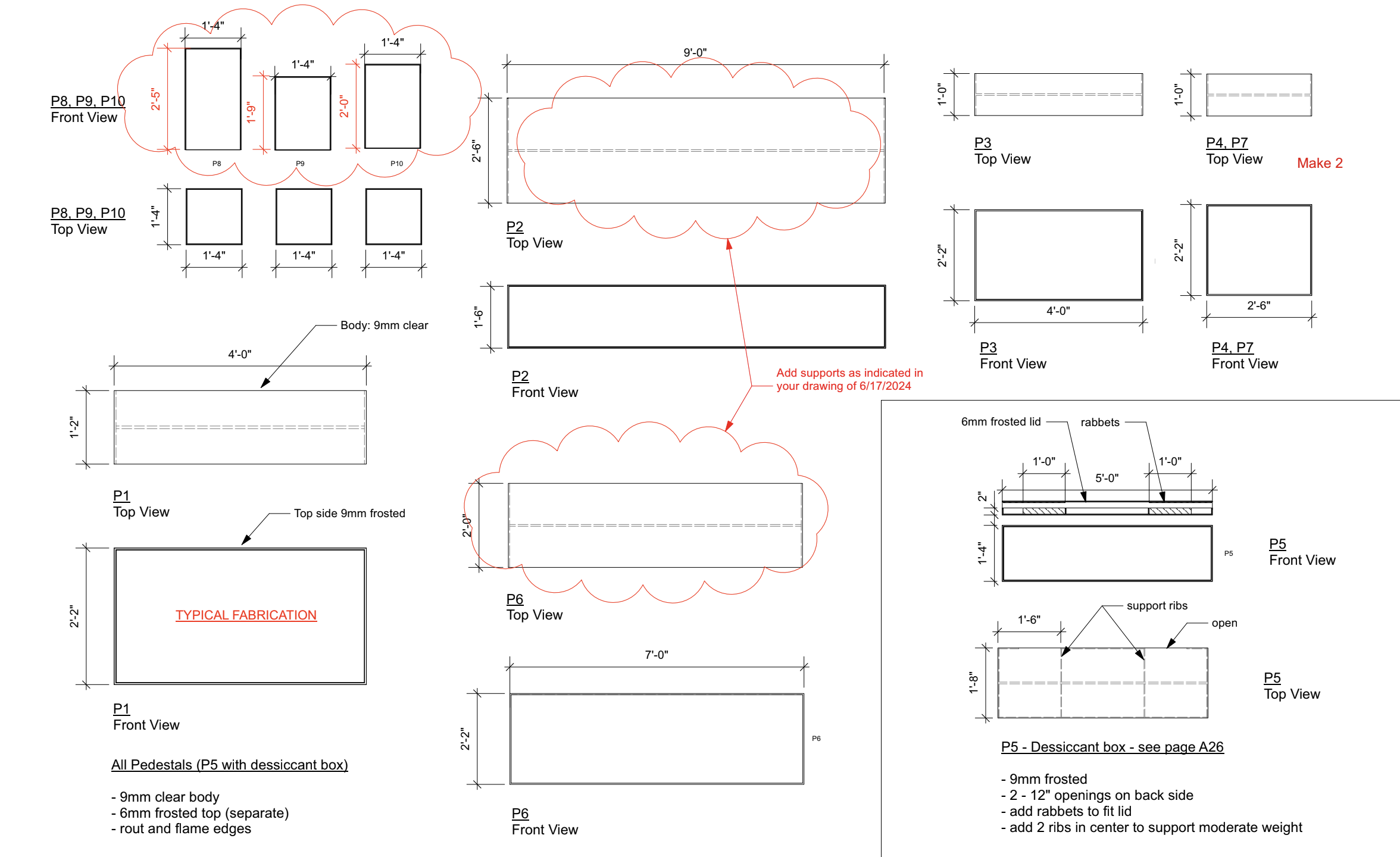

Detailed shop drawings with part dimensions for a modular pedestal called out.

Installed exhibit featuring modular display cases and pedestals built from the design concept.

Second view of the installed modular exhibit display system showing final materials and proportions.

Design Support Across Materials, Displays, and Architectural Systems

Our design services support a wide range of fabrication scopes, ensuring design intent carries through from CAD development to final installation.

High-Performance Material Selection

We design with a variety of specialized plastics selected for clarity, strength, and long-term durability:

Acrylic (PMMA): Standard and custom Acrylic Sheets.

Museum Quality: Tru Vue Optium Museum Acrylic for conservation-grade protection.

Engineering Plastics: Polycarbonate, Lumasite, and UHMW for high-impact architectural applications.

Custom Display & Museum Vitrines

Our process accounts for material behavior, tolerances, and access requirements—especially for collectors and institutions.

Architectural Wine Storage

We design integrated systems that combine acrylic, metal, and wood to achieve high bottle density and clean sightlines.

Acrylic Wine Cellars (residential and commercial)

Multi-Material Architectural Systems

When projects extend beyond plastics, we support complex Multi-Material Assemblies, combining:

Solid Surface (Corian)

Wood Cabinetry (check out our cabinetry brand Miremont Millwork)

Metal Components and Hardware

Design Deliverables, File Formats, and Revision Control

We can start from rough inputs and scale the documentation to match your project. The more complete the inputs, the faster we can respond and the fewer revision cycles you will need.

Common deliverables

Fabrication-aware CAD development as needed for buildability, fit, and assembly.

Shop drawings with critical dimensions, notes, and installation considerations.

Material and thickness callouts, finish expectations, and seam strategy where applicable.

Hardware notes when relevant (hinges, glides, magnets, fasteners, standoffs).

Prototype plan and acceptance criteria when prototyping is required.

Revision control so changes stay coordinated from design through fabrication.

Preferred file formats

.dxf and .dwg

Accepted file formats

Send us what you have, we can usually convert them to our desired formats.

Pricing and Quote Factors

Design pricing depends on scope and how defined the project is when it arrives. These factors drive cost and timeline.

Starting point (rough concept vs. dimensioned drawings vs. existing CAD).

Complexity (multi-part assemblies, tight tolerances, visually critical finishes, access requirements).

Number of iterations expected and stakeholder approvals.

Prototype requirement and number of prototype cycles.

Documentation scope (concept review only vs. production-ready shop drawings and release package).

Timeline (standard vs. expedited).

Coordination needs (multi-material integration, vendor coordination, installation constraints).

What We Need To Review Your Project

Providing clear inputs helps us respond quickly and accurately.

Drawings, sketches, or CAD files (if available).

Overall dimensions and quantities.

Target timeline or installation date.

Finish expectations and tolerance sensitivity.

Installation environment and constraints.

Shipping destination.

Send what you have. We’ll respond with feasibility feedback and clear next steps.

Why Design Teams Choose Architectural Plastics

Our design process is built to support complex projects where precision, finish quality, and execution matter.

Design that respects materials and fabrication realities.

Single team from concept through fabrication.

Experience with large-format, high-precision, and visually critical work.

Problems solved early, before they become expensive.

Want To Learn More About Our Fabrication Offerings?

FAQs

Can you start from a rough idea or sketch?

Yes. That’s common. We’ll translate it into buildable geometry and clear fabrication intent.

Do you only do design, or do you fabricate too?

We do both. Design is most valuable when it leads directly into production-ready execution.

What software do you work in?

We commonly work with Autodesk CAD tools, Fusion 360, SketchUp, and Cabinet Vision. If your team has a preferred format, send what you have and we’ll align where possible.

Can you support prototypes and then scale to production runs?

Yes. That’s a core use case. The goal is repeatability, not just a one-off.

Can you review existing drawings or CAD for manufacturability before we release it?

Yes. We can review for buildability, tolerance risk, finish strategy, and installation constraints before you commit to production.

What do you need to quote design support?

A sketch, drawing, or CAD file (if available), overall dimensions, quantity, deadline or installation date, finish expectations, and any known constraints.

Do you work directly with architects, exhibit designers, and outside project teams?

Yes. We regularly collaborate with external teams and coordinate design intent into fabrication-ready documentation.

Can you value-engineer a design to meet a budget or lead time?

Yes. We can recommend material and process alternatives, seam strategies, and fabrication approaches to reduce risk and control cost.

How do you handle revisions and coordination?

We use revision control so changes stay tracked and production intent stays clear from design through fabrication.

Can you design across multiple materials, not just plastics?

Yes. We often design systems that combine plastics with wood, solid surface, and metal so assemblies build efficiently and install cleanly.

Can you match an existing part or system and redesign it for better manufacturability?

Yes. Design and manufacturing feasibility studies are typical for most of our projects. Whether you’re pressure-testing an idea or preparing for production, our design team helps you move faster with fewer surprises.

Ready to move forward?

If you’re deciding whether a concept is viable or how to execute it, this is where to start.

Already have drawings? Email them to us directly for the fastest feedback: sales@archplastics.com