Light Fixtures

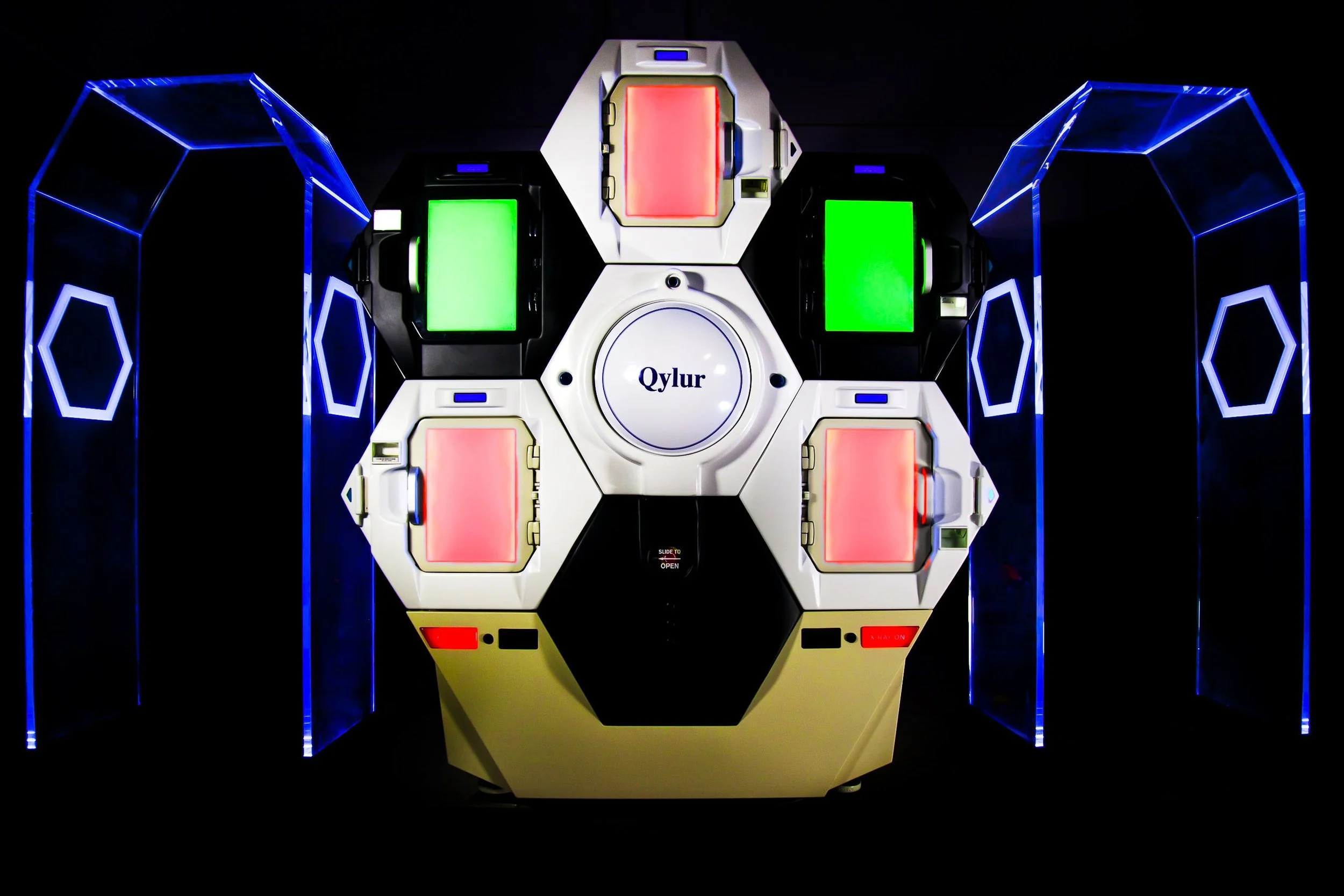

Architectural Plastics fabricates custom light fixtures and illuminated assemblies for architects, designers, brands, and builders who need clean geometry, premium finish, and reliable execution. We specialize in plastic components that make lighting look sharp: diffusers, lenses, illuminated panels, and light-ready assemblies that integrate cleanly with metal and wood structures.

We can build from your drawings, collaborate during design development, or fabricate to match an existing fixture style. The goal is straightforward: lighting that reads high-end up close and is practical to install and service.

What We Fabricate

Acrylic and polycarbonate diffusers and light covers

Edge-lit and back-lit acrylic panels

Frosted, textured, and light-diffusing components

Thermoformed lenses and curved diffusers

Bonded acrylic assemblies for illuminated features

Multi-material housings and mounts (plastic + wood + metal integration)

Light-ready parts with planned access, fasteners, and wire pass-throughs

Built for Clean Light and Clean Details

Lighting projects fail for predictable reasons: glare, hot spots, visible fasteners, awkward access, and sloppy finishing. We build around the realities that matter in the field.

Typical considerations we design and fabricate around:

Diffusion level and uniformity (reducing hot spots)

Surface finish and clarity (frosted vs opal vs clear)

Edge quality and seam strategy for close viewing

Access for maintenance and driver replacement

Concealed fasteners and clean mounting interfaces

Repeatability for multi-unit runs and consistent installs

Materials and Finishes

Material choice depends on the lighting goal and the environment. We commonly build with acrylic and polycarbonate and can advise on finish options that control glare and diffusion.

Common finish approaches include:

Frosted and light-diffusing surfaces

Polished show edges where required

Bonded clear seams for premium visual performance

Formed geometry for curved or wrapped illumination

From Prototype to Production

If this is a new fixture design, prototyping is usually the fastest path to confidence. We can validate diffusion, fit, access, and finish before moving into repeat builds.

For production runs, we build for consistency: stable geometry, controlled processes, and packaging that protects high-finish parts during transport.

Coordination for Electrical and Installation

We fabricate the physical components and assemblies. For electrical integration, final wiring, and code compliance, we coordinate around your electrician, lighting vendor, or engineer as needed. If your project requires certification or specific compliance requirements, call that out early so the design supports it.

What to Send for a Quote

To quote a light fixture or illuminated assembly quickly, send:

Overall dimensions and target visual effect (diffused, edge-lit, back-lit, etc.)

Material preference (or environment and durability requirements if you’re unsure)

Quantity (prototype, short run, production)

Deadline and ship-to city

Drawings or CAD files (preferred), or a dimensioned sketch plus reference images

Notes on access requirements and mounting constraints

FAQ

Can you match a specific diffusion look or glare control requirement?

Yes. Send reference images and describe the environment and viewing distance. We’ll recommend material and finish options that achieve the effect.

Do you build curved lenses or formed diffusers?

Yes. Thermoforming is often the right approach for curved diffusion and wrapped illumination.

Can you build the housing as well as the diffuser?

Yes. We can fabricate multi-material housings and mounting structures and coordinate metal components as needed.

Can you do prototypes and production runs?

Yes. We support one-off prototypes through repeat builds and production quantities.

Do you handle electrical wiring and certification?

We fabricate the fixture components and assemblies and coordinate electrical integration with your licensed electrician or lighting vendor. If certification or compliance is required, share those requirements early.