Museum-Grade Acrylic Bonding for Flawless Seams and Complex Custom Assemblies

Architectural Plastics is an industry leader in custom acrylic bonding for projects where seam quality, alignment, and optical clarity cannot be compromised. We build museum-grade display cases, pedestals, vitrines, and presentation-critical acrylic assemblies that need to look flawless up close, under real lighting, and in high-visibility environments.

Our bonding work is engineered, not improvised. Seam placement is planned around sightlines and use-case. Joint preparation and fixturing are controlled so assemblies cure square, stable, and distortion-free. The result is clean, intentional seams with structural confidence—whether you’re building a one-off showpiece, a complex angled assembly, a seamed panel system, or a repeat production run that must match unit-to-unit.

We also support complex glue-ups beyond acrylic, including solid surface laminations and glue joints where stability and finish quality matter just as much as strength. If you need a finished result that installs cleanly and holds up over time, this is the level of bonding discipline you’re looking for.

If you have drawings, dimensions, or an existing prototype, send what you have. We’ll review feasibility and recommend the right bonding approach before work begins.

Fastest response: sales@archplastics.com . Send drawings, CAD, or sketches — PDFs are fine.

Clear acrylic bonding with controlled seam placement and alignment

Structural bonding for displays, pedestals, and multi-panel assemblies

Optical-grade results for customer-facing and museum-level work

Bonding integrated with CNC machining and finishing workflows

Repeatable processes for prototypes through production runs

Plastic Bonding Examples

Representative examples of clear acrylic bonding used for displays, pedestals, wine racks, and structural assemblies where seam quality, alignment, and long-term stability matter.

Hand-applied acrylic bonding with controlled adhesive flow and seam alignment for clear display assemblies.

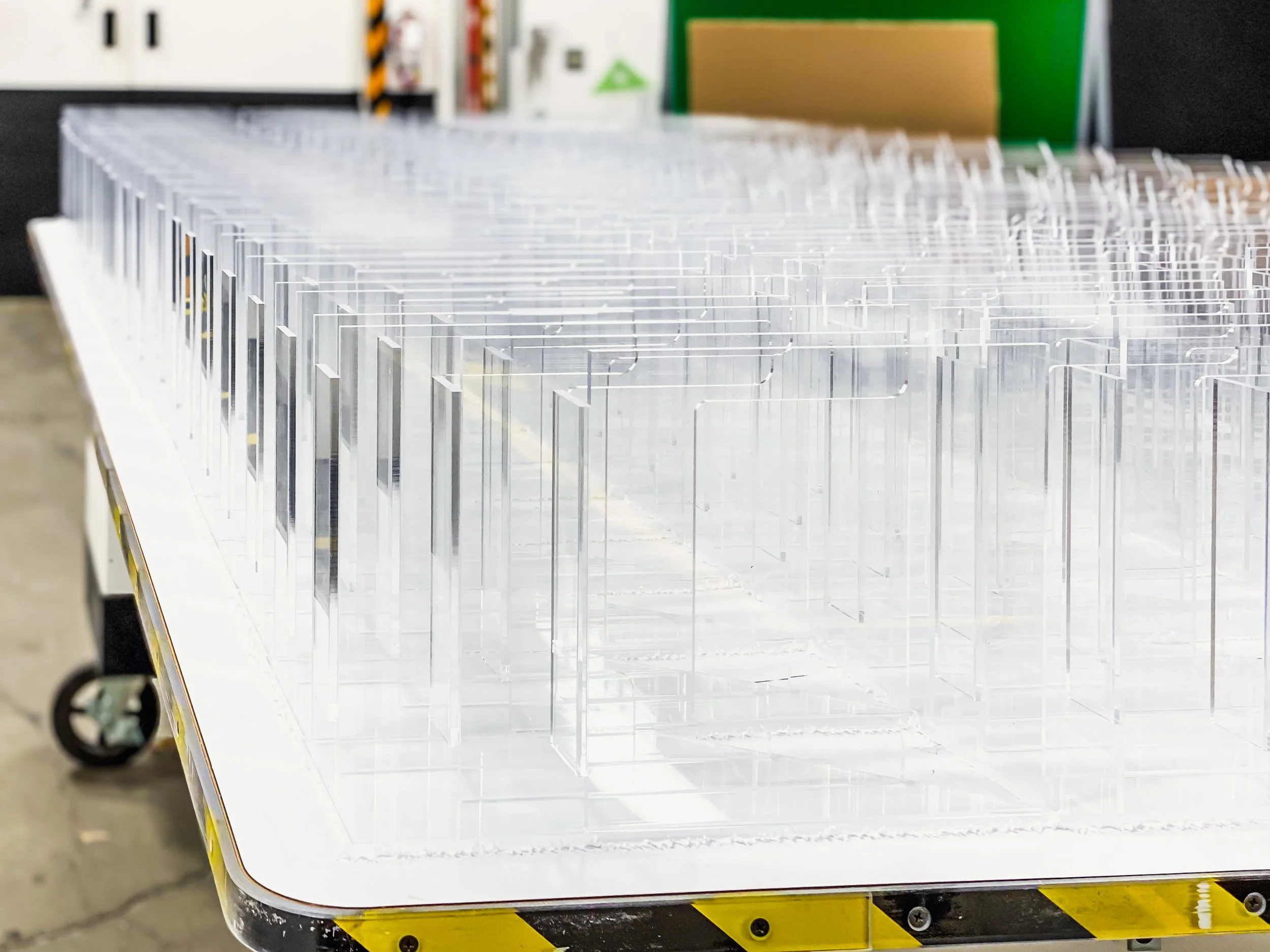

Clear acrylic structural units and assembled on production tables for repeatable alignment and strength.

Bonded clear acrylic display cases staged after assembly, showing seam clarity and structural consistency.

Bonded acrylic display cases used in a high-visibility retail installation, requiring clean seams and optical clarity.

Bonding Capabilities and Applications

Acrylic Display Cases & Pedestals

We bond clear acrylic display cases and enclosures where seam quality, alignment, and optical clarity matter. Bonding strategy is planned around viewing angles, access needs, and long-term stability so finished cases present cleanly in real lighting and assemble without stress.

Best For:

Museum and gallery displays, collectibles, product protection, high-visibility presentations.

You receive:

Clean, consistent seams designed around viewing angles.

Bonded corners and joints aligned for square fit and stable geometry.

Finish planning so edges and seams present correctly.

Retail Displays

Retail environments punish sloppy seams. We bond acrylic components for brand-facing displays that must look intentional, ship safely, and install without field fixes. Bonding is coordinated with CNC machining, hardware, and packaging requirements so the final assembly is install-ready.

Best For:

Luxury retail fixtures, branded product displays, multi-material assemblies.

You receive:

Bonded acrylic components built for handling and installation.

Consistent seam quality across sets.

Packaging-aware builds to reduce damage risk in transit.

Angled Glue Seams

Angled glue joints demand more control than square box seams. The joint geometry amplifies small alignment errors and can make stress, gaps, or optical distortion far more visible. We bond angled acrylic assemblies with deliberate joint prep, controlled fixturing, and cure discipline so seams land clean, stay stable, and present correctly in real lighting.

Best For:

Angled acrylic assemblies, mitered corners, chamfered joints, and faceted display components.

You receive:

Seam placement planned around sightlines and light.

Controlled fixturing to hold angle and alignment through cure.

Joint prep and bonding approach designed to reduce stress and optical imperfections.

Production Runs

Production bonding requires process discipline. We build repeatability through standardized joint prep, controlled setups, and consistent cure handling so multi-unit runs match the first article. This is where one perfect prototype becomes a consistent production result.

Best For:

Repeat orders, multi-unit case sets, fixture components, standardized assemblies.

You receive:

Repeatable seam quality across runs.

Setup control to reduce variation unit-to-unit.

Predictable assembly flow for delivery schedules.

Seamed Panels

When a single piece isn’t possible, seam strategy matters. We seam acrylic panels to create larger surfaces while controlling visibility, alignment, and long-term stability. The goal is not just bonded, but flat, clean, and visually intentional.

Best For:

Large clear panels, tall enclosures, architectural glazing-style assemblies.

You receive:

Seam placement planned around sightlines and lighting.

Stable alignment across the seam to reduce distortion.

Finish planning for edges and transitions.

Large Format Glue Ups

Large format glue ups introduce risk: weight, handling, clamping/fixturing, and cure behavior all scale up. We build large acrylic assemblies with controlled handling and staged processes so finished components remain stable, square, and presentation-grade.

Best For:

Oversized assemblies, large structural components, high-value clear builds.

You receive:

Fixturing and handling planned to protect surfaces and alignment.

Staged bonding approach for stability and repeatability.

Build strategy coordinated with packaging and shipping requirements.

Complex Geometries

Complex acrylic assemblies amplify bonding risk. Small alignment errors become visible fast, and stress can show up if joint prep, fixturing, and cure control aren’t disciplined. We bond multi-part forms where geometry, finish, and optical clarity all matter, keeping seams intentional and alignment stable through cure.

Best For:

3D acrylic assemblies, bonded geometric forms, precision fit-ups, sculptural components.

You receive:

Controlled fixturing to hold alignment through cure.

Seam strategy matched to sightlines and finish requirements.

Bonding approach designed to reduce stress and optical artifacts.

Custom Acrylic Furniture

Furniture-grade acrylic has no place to hide mistakes. We bond and finish clear acrylic furniture where seam quality, edge clarity, and long-term stability matter under real lighting and daily use. The goal is a clean, intentional look with structural confidence—not “shop project” acrylic.

Best For:

Custom acrylic furniture, display furniture, showroom pieces, high-visibility residential or retail environments.

You receive:

Seam placement and bonding strategy planned for visibility and strength.

Controlled cure and handling to reduce stress and optical distortion.

Finish planning so edges and seams present cleanly in real lighting.

Laminations

Laminations require disciplined bonding to avoid trapped air, distortion, and visible glue lines. We laminate acrylic to build thickness and structural components while maintaining clarity and dimensional stability. The process is planned around bond-line control, clamping strategy, and finish requirements so the final piece machines and presents cleanly.

Best For:

Thickness build-ups, structural acrylic bases, large bonded slabs, custom furniture components.

You receive:

Controlled lamination process to reduce bubbles and distortion.

Stable bonded thickness suitable for machining and finishing.

Clean finished edges aligned with presentation requirements.

Materials We Bond and Assemble

We bond a wide range of plastics and composite materials depending on performance requirements, finish expectations, and production goals. Most work centers around clear acrylic, but we also build multi-material assemblies and glue-ups where bond strength, alignment, and long-term stability matter as much as visual clarity. If you’re value engineering a large run, we can prioritize repeatability and throughput.

If the seam is a focal point, we use bonding methods designed for the cleanest possible presentation in real lighting.

Common Materials We Bond and Assemble

Acrylic (PMMA) (Clear, frosted, and color acrylic)

Polycarbonate (Impact-resistant assemblies and guards)

Solid surface (Corian glue-ups, laminations, and seamed panels)

Mixed-material assemblies (Acrylic integrated with wood, metal, and hardware)

Bonding and Assembly Specs

Typical CNC tolerance range: +/- 0.010” on CNC-machined features.

High-precision CNC tolerance range: Up to +/- 0.005” on qualifying features.

Tolerance caveat: Final results depend on material, geometry, part size, bonding sequence, and fixturing. We confirm tolerance sensitivity during quoting and align expectations before work begins.

Seam visibility caveat: Seam visibility is driven by geometry, thickness, edge preparation, viewing distance, and lighting conditions. We plan seam placement and finish expectations up front so the result matches the application.

Bonding Methods and Seam Requirements

We select bonding methods based on the application. Seam visibility is not guesswork. If the seam is a critical visual element, we confirm seam placement, joint geometry, edge preparation, and finish strategy before fabrication starts.

For production runs, we can use faster, repeatable bonding approaches designed for consistent unit-to-unit results.

For high-visibility work, we use bonding methods that prioritize seam clarity, minimal distortion, and long-term stability.

Bonding Pricing and Quote Factors

Bonding cost is driven by the variables below. Sharing these details up front helps us quote accurately and avoid change orders mid-build.

Seam requirement (optical-grade seams vs functional seams).

Thickness, seam length, and joint geometry (angled seams require more control).

Edge preparation and fit-up requirements (a major driver of seam quality).

Assembly size, handling complexity, and fixturing requirements.

Finish level after bonding (edge finishing, polishing, show surfaces).

Quantity and repeatability (prototype vs production run).

Packaging and shipping requirements (finish sensitivity, crating, delivery constraints).

Timeline (standard vs expedited).

What To Send For a Fast Bonding Quote

Send drawings, CAD, or a sketch with key dimensions. Include material type and thickness, quantity, finish expectations, and the install environment if the work is high-visibility. If you’re unsure on the bonding approach, send photos or references and we’ll recommend the right method.

FAQs

Do you only bond acrylic?

No. Acrylic is the most common, but we also bond polycarbonate and perform solid surface glue-ups and laminations. We also build multi-material assemblies that integrate wood, metal, and hardware.

Can you produce nearly invisible seams?

Yes, when the design and viewing conditions allow. Seam visibility depends on geometry, thickness, edge preparation, viewing distance, and lighting. We plan seam placement and finish expectations up front so the result matches the application.

Do you support production runs?

Yes. We bond one-off prototypes through repeat production runs. For multi-unit builds, we standardize setups and process controls so units match.

Can you bond large panels or oversized assemblies?

Yes. We handle seamed panels and large format glue-ups using controlled handling and fixturing to maintain alignment and long-term stability.

How do you decide which bonding method to use?

We choose bonding methods based on seam requirement, structural needs, cycle time, and long-term stability. Production runs typically prioritize repeatability and throughput. High-visibility work prioritizes seam clarity, minimal distortion, and finish.

Can you hold tight tolerances on bonded assemblies?

We hold typical CNC-machined feature tolerances of +/- 0.010”, with high-precision features up to +/- 0.005” on qualifying geometries. Final assembly results depend on material, part size, bonding sequence, and fixturing, so we confirm tolerance sensitivity during quoting.

Can you bond acrylic to polycarbonate or mixed plastics?

It depends on the application, geometry, and performance requirements. Send your materials and use-case and we’ll recommend the right approach.

Do you polish edges and show surfaces after bonding?

Yes. We coordinate bonding with finishing so seams, edges, and show surfaces present correctly in real lighting. If only certain edges are visible, call that out and we’ll plan the finishing accordingly.

Ready to Move Forward?

If your project depends on clean seams, stable alignment, and a finished result that holds up in real use, send what you have and we’ll respond with clear next steps.

Already have drawings? Email them to us directly for the fastest response: sales@archplastics.comPhone: 707-765-9898