Medical Devices and Clean Rooms

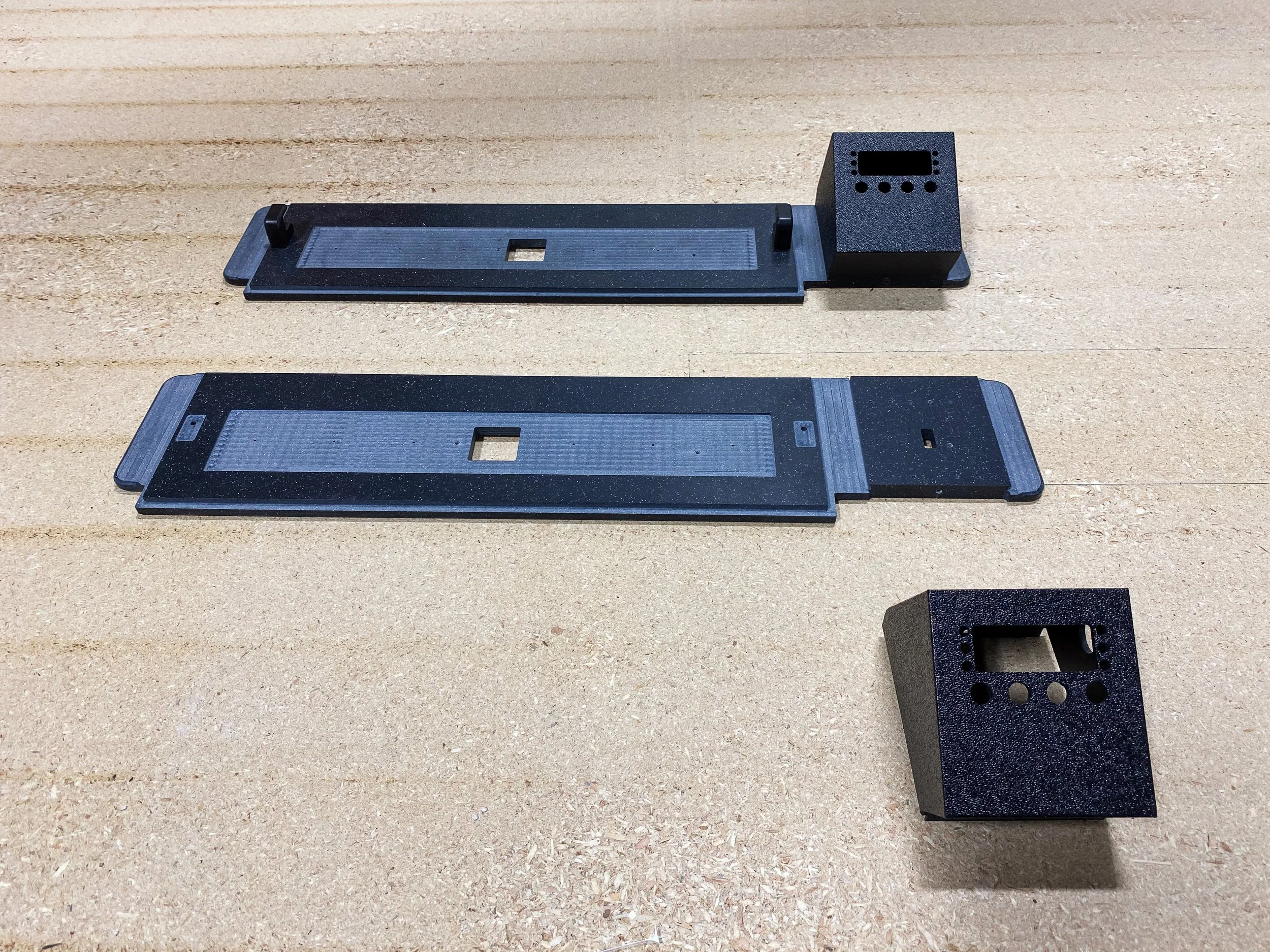

Architectural Plastics fabricates precision plastic components and assemblies for medical, laboratory, and clean-room environments where consistency, fit, and finish matter. We support B2B teams that need reliable execution—prototypes through production runs—with processes designed for repeatability.

Whether you’re developing a device, building lab infrastructure, or specifying clean-room components, we build around the realities that matter: dimensional accuracy, controlled assemblies, surface finish, and practical serviceability.

Typical Deliverables

Guards, covers, and protective enclosures

Machine panels, access doors, and equipment housings

Clear viewing panels and inspection covers

Trays, bins, and repeat components for handling and workflow

Bonded acrylic assemblies where clarity and seam quality matter

Multi-material assemblies integrating plastics with metal and wood when required

Capabilities That Support Clean Environments

We fabricate primarily in plastics and support projects that require controlled, consistent outputs:

CNC machining for repeatable geometry and tight interfaces

Drilling, countersinks/counterbores, and hardware-ready part prep

Bonding and assembly with disciplined fit-up and seam planning

Polishing and edge finishing for clean presentation and durability

Thermoforming for shaped components when geometry requires forming

Packaging and shipping planned to protect finish-critical components

Built for Repeatability

In medical and lab-adjacent environments, “close enough” becomes expensive. We build for repeatability so parts fit and assemble the same way across single prototypes, pilot runs, and production quantities. If you call out critical dimensions or interfaces, we’ll confirm a realistic machining and tolerance plan up front.

Materials and Fit-for-Use Guidance

Material choice depends on the environment and performance needs—clarity, impact resistance, chemical exposure, stiffness, and surface durability. We commonly work with acrylic and polycarbonate, along with common engineering plastics such as HDPE, UHMW, PVC, and ABS. If your project has a required grade, color, or spec, share it early so we can confirm availability and suitability.

How to Start a Project

If you have CAD and drawings, send them. If you don’t, send reference photos, a dimensioned sketch, and the functional requirements. We’ll help confirm manufacturability, finish targets, assembly approach, and the fastest path to a first article.

FAQ

Do you support prototypes and production runs?

Yes. We support one-offs, pilot runs, and repeat production quantities.

Can you hold tight tolerances?

Yes, within the practical limits of material, geometry, and part size. If you call out critical interfaces, we’ll confirm a tolerance plan before cutting.

Do you fabricate clear panels and covers for inspection visibility?

Yes. Clear acrylic and polycarbonate are common for guards, covers, and viewing panels.

Can you deliver assembled components, not just parts?

Yes. We regularly deliver assemblies and multi-material builds when required.

Do you handle certified clean-room manufacturing?

We build components intended for clean environments, but if your project requires specific certifications or validated clean-room manufacturing procedures, tell us up front so we can align the scope appropriately.