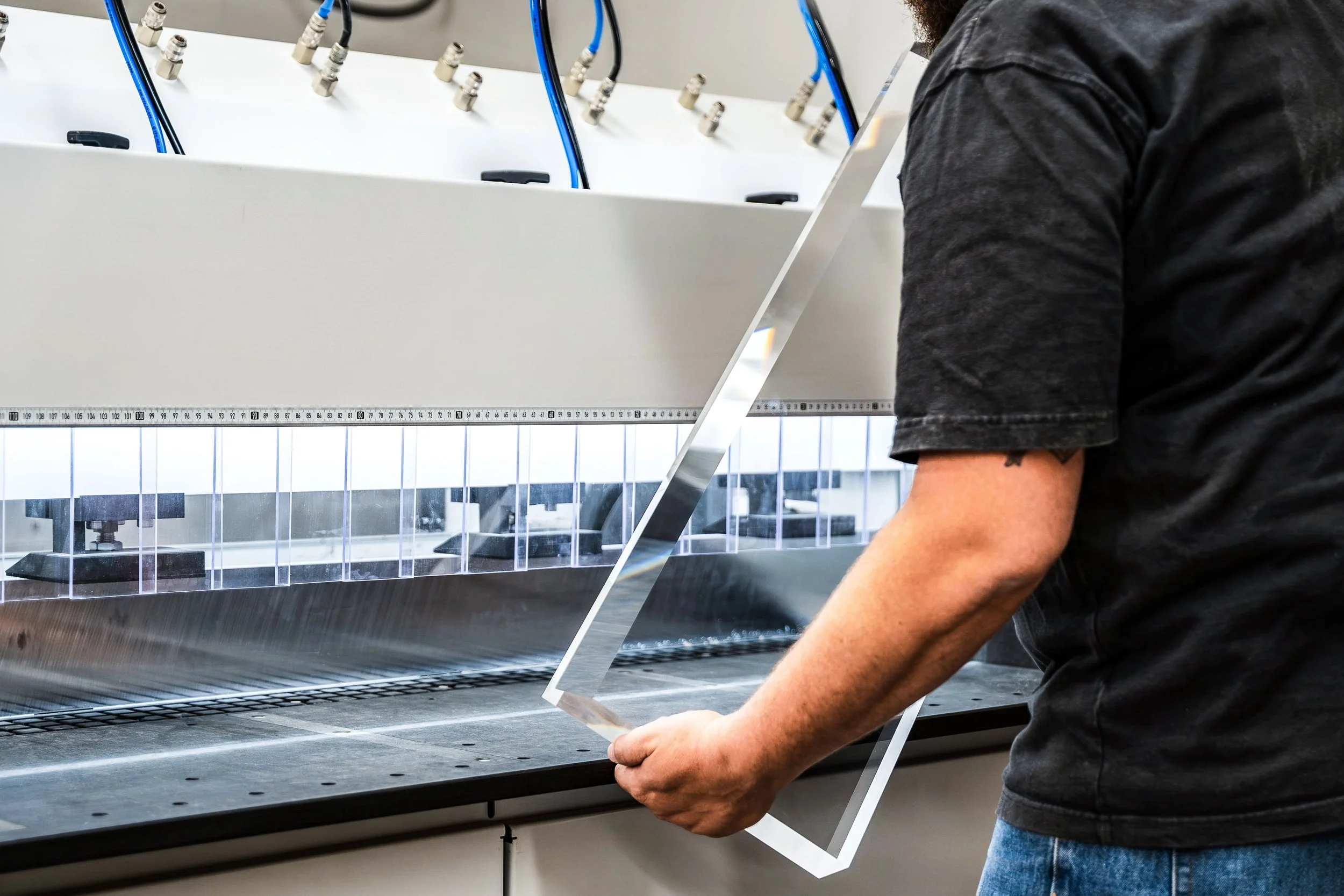

Acrylic Polishing

Edge Polishing + Surface Polishing for Premium Clarity

Acrylic polishing is the difference between “finished” and truly premium. We provide both edge polishing and surface polishing to achieve clear, distortion-free results for display cases, furniture, architectural panels, and precision-fabricated parts.

We specialize in acrylic edge polishing and surface polishing for premium clarity—prototype through production.

We offer three primary polishing methods—diamond-tool machine polishing, hand buff polishing, and flame polishing—and we’ll recommend the right approach based on part geometry, finish expectations, and production requirements.

Acrylic Edge Polishing

Edge polishing is the most common way acrylic projects level up fast. A polished edge increases clarity, improves perceived quality, and brings out the depth that makes acrylic look “glass-like” without the fragility of glass.

We polish:

Straight edges, long edges, and multi-part assemblies

Beveled edges and detail edges

Thick acrylic edges (including heavy, high-end applications)

Production parts where repeatability matters

If you need consistent, repeatable edge results across many parts, diamond-tool machine polishing is usually the best fit. If you need the absolute highest cosmetic finish on a show edge, sanding and then hand buff polishing is often the top tier.

Acrylic Surface Polishing

Surface polishing is used to refine show faces on new fabrication when the application demands a higher cosmetic finish. It’s commonly used for display, furniture, and architectural work where the surface will be viewed up close under strong lighting.

We can:

Improve clarity and uniformity on show faces

Reduce light machining marks from normal fabrication processes (when appropriate)

Refine surfaces prior to final assembly when the finish requirement is premium

Surface polishing is more variable than edge polishing because results depend on geometry and the finish standard required. We do not refurbish third-party parts. If surface polishing is needed, we quote it as part of fabrication we control from start to finish.

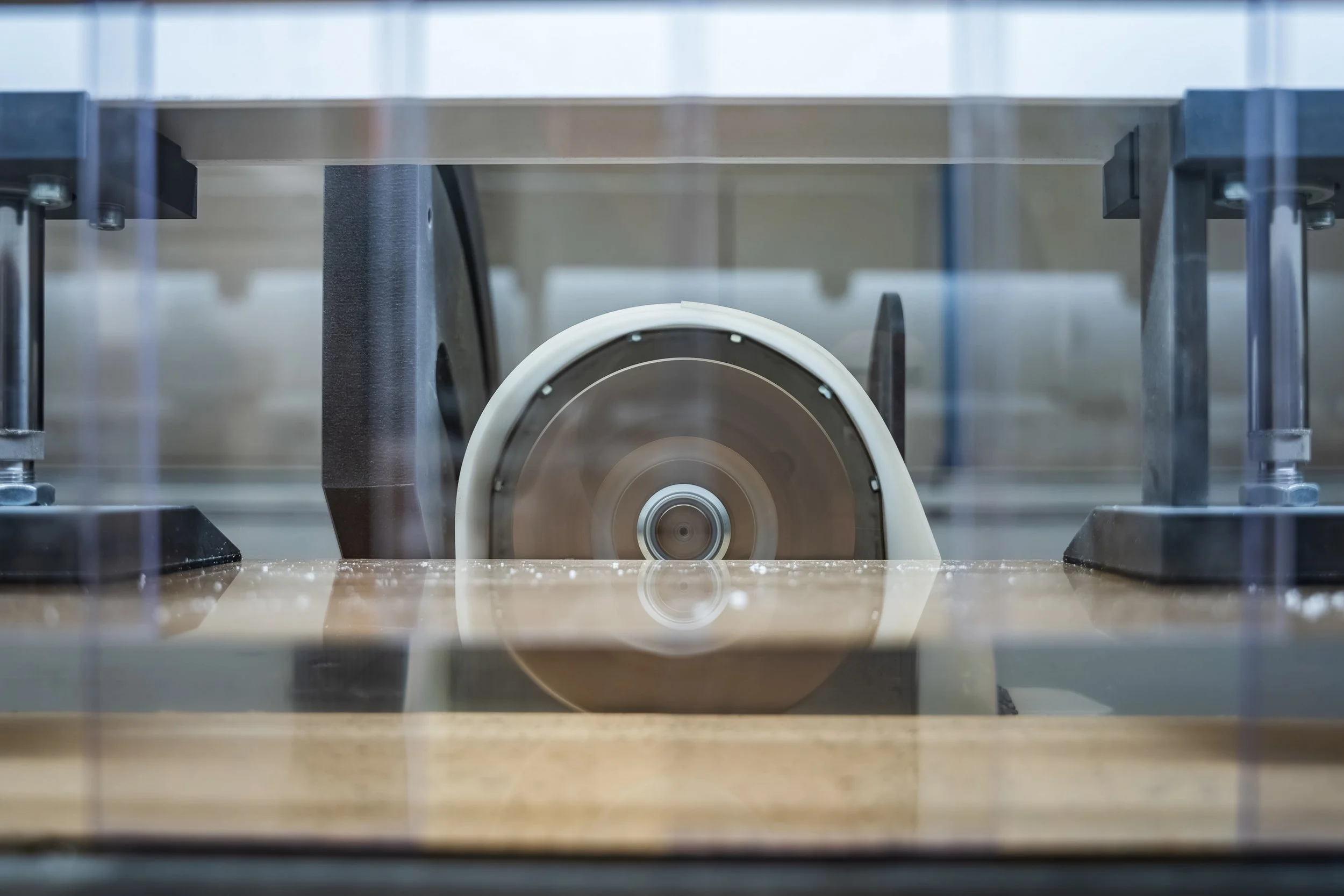

Diamond-Tool Machine Polishing (Automated)

Machine polishing produces a high-clarity finish with excellent consistency. It’s ideal when you need repeatable results across multiple parts, long runs, or tight process control.

What it’s best for:

High-volume or repeatable parts

Long straight edges and uniform bevels

Thick acrylic edges requiring a clean, consistent finish

Parts where the finish must be consistent from piece to piece

Capabilities note: We can diamond-tool machine polish acrylic up to 4" thick (including stacked polishing up to 4").

Hand Buff Polishing (Highest Cosmetic Finish)

Buff polishing is the most presentation-grade option and typically follows sanding or machine polishing prep. This premium method is often used for high-end work where the finish will be inspected up close.

What it’s best for:

Furniture-grade edges and show faces

One-off pieces and premium prototypes

Parts where the final finish is inspected up close

Tradeoff: Buff polishing typically takes more time than machine polishing, especially on complex shapes or large quantities.

Flame Polishing (Fast, Clean, Best for Select Use Cases)

Flame polishing is a fast way to improve edge clarity when the application and geometry are a good match. It’s commonly used when speed matters and the finish requirement is clean and glossy, not necessarily smooth and perfect under close inspection.

What it’s best for:

Simple edges on appropriate geometries

Parts that benefit from quick cosmetic improvement

Projects where speed matters and expectations are clear

Important note: Flame polishing can reveal or preserve faint machining marks underneath depending on the starting edge quality. If you need the highest cosmetic finish, sanding and buff polishing is usually the better choice.

Choosing the Right Finish

Utility (glossy, router marks may remain)

Recommended: Flame polishing. Best when safe, glossy edges matter but ultra-premium cosmetics are not the goal.

Clean Finished (clear, consistent, repeatable)

Recommended: Diamond-tool machine polishing. Best for long edges, bevels, and production parts where consistency matters.

Presentation-Grade / Furniture-Grade (premium, inspected up close)

Recommended: Sanding or machine prep followed by buff polishing. Best for show edges, luxury fixtures, display work, and furniture.

If you’re not sure, tell us where the part will live (museum display, retail, furniture, industrial, etc.). We’ll recommend the correct method.

Capabilities

Edge polishing and surface polishing

Diamond-tool machine polishing up to 4" thick (including stacked polishing up to 4")

Beveled edges and clean, consistent edge finishes

Hand buff polishing for premium cosmetic results

Options suited for prototypes through production runs

What We Need to Quote Polishing Work

To price and schedule accurately, send:

Material type (cast vs. extruded if known) and thickness

Part dimensions and which edges and/or faces need finishing (edge lengths help)

Quantity (one-off, small batch, or production run)

Finish expectation (utility, clean finished, furniture-grade)

Deadline and delivery location (pickup or shipping)

Notes on the application (display, furniture, architectural, industrial) and any critical cosmetic requirements

FAQs

Do you polish both edges and surfaces?

Yes. We do edge polishing and surface polishing, and we’ll recommend the right approach based on part geometry, finish expectations, and production requirements.

Which method gives the best finish?

For the highest cosmetic finish on show edges and premium work, sanding and then buff polishing is typically the top tier. For repeatable clarity at scale, diamond-tool machine polishing is usually the best fit.

Can you polish thick acrylic?

Yes. We can diamond-tool machine polish acrylic up to 4" thick (including stacked polishing up to 4").

Is flame polishing “as good as” buff polishing?

Not usually. Flame polishing can look great in the right application, but buff polishing is generally superior when the finish will be inspected closely.

Do you refurbish existing acrylic parts made by others?

No. We don’t refurbish third-party parts. For premium results, we quote polishing as part of fabrication we control from start to finish.