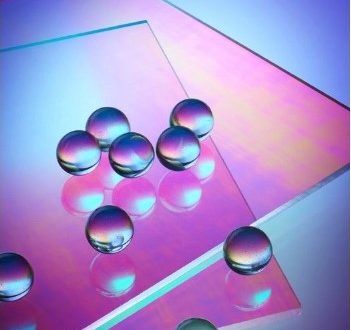

ACRYLITE Reflections Iridescent Acrylic Sheets

Rainbows never cease to fascinate us. We gaze at them in wonder and amazement. With their brilliant colors and awesome dimensions, they capture the attention of children and adults alike. Take advantage of this magical play of colors for your displays, signs and store fixtures by using ACRYLITE Reflections iridescent acrylic sheet.

Features & Benefits

- changes color depending on the viewing angle

- uses ambient light to create its own lighting effects

- produces mirror-like reflections

- shines in every color of the rainbow

- easy to saw, mill, drill, bend and polish

- can be thermoformed into almost every desired shape

ACRYLITE Reflections iridescent sheet is the ideal material for designing eye-catching items, attention-grabbing displays, effective signs and dynamic, colorful tradeshow booths and store fixtures. It is a beautiful addition to the ACRYLITE sheet product line and a real inspiration for all designers and creative professionals.

Fabricating Recommendations

ACRYLITE Reflections iridescent sheet has a surface coating on one side that is responsible for the lighting effects. The following recommendations take this special feature into account during handling and fabrication.

ACRYLITE Reflections iridescent can be fabricated with the same parameters and equipment as standard acrylic sheets. Correct positioning of the coated surface is essential in order to obtain perfect fabrication results.

Cleaning

Clean ACRYLITE Reflections iridescent sheet with mild soap and lukewarm water or ACRIFIX AC 1010 Anti-Static Cleaner. Use a soft, clean cloth and gentle pressure (no rubbing). Make sure not to scratch the coated surface, because scratches cannot be removed by polishing this side of the sheet.

Machining

ACRYLITE Reflections iridescent sheet can be sawn, drilled, milled and edge-machined like standard ACRYLITE extruded acrylic sheet, provided the coated surface is positioned at the correct angle to the machining tool. Make sure that the cutting tools used for sawing, drilling, routing and edge treatment enter the coated surface and exit through the uncoated surface.

Bonding

Adhesives suitable for standard ACRYLITE extruded sheet are also compatible with ACRYLITE Reflections iridescent sheet. Since ACRYLITE Reflections iridescent sheet is partially transparent, it is important that adhesive joints remain almost invisible on the uncoated surface. The uncoated surface of ACRYLITE Reflections iridescent can be easily bonded to standard ACRYLITE sheet, providing comparable final bond strength.

However, the final bond strength does differ noticeably when bonds are made with the coated surface. The bond with the coated surface can be improved to a certain extent using cyanoacrylate adhesives. Where high bond strengths are required, we recommend removing the surface coating in the area to be bonded.

If polyester tape is used to assist with bonding, please remove the strips of tape carefully after bonding is completed, pulling them off from the surface towards the edge. That avoids delamination of the coating at the edges.

ACRIFIX Special Bonding Agents manufactured by Evonik are the perfect complement for cementing ACRYLITE sheet products. When bonding the uncoated side of ACRYLITE Reflections iridescent sheet, ACRIFIX® 1S 0117 Pure or ACRIFIX® 1S 2105 Express are recommended. These solvent cements have superior capillary action for better flow through, and dry quickly with a strong bond and attractive appearance. ACRIFIX 1S 0117 is the only non-methylene chloride solvent cement in the North American market.

Linear Heating/Line-Bending

ACRYLITE Reflections iridescent sheet can be bent simply and quickly on standard line-bending machines. For best results, the coated side of the sheet should be on the side exposed to tensile stress (outer side of bend). At small bending radii, heat the uncoated side of the sheet. At large bending radii of more than 90°, it is advisable to heat the coated side.

Thermoforming/Stretch Forming

You can thermoform ACRYLITE Reflections iridescent sheet to obtain a variety of shapes. If only one side of the sheet is heated, the coated surface should face the heat source.

ACRYLITE Reflections iridescent sheet is also suitable for moderate stretch forming using compressed air. In this case, and during thermoforming, the coated surface of the sheet should be on the side exposed to tensile stress (outer side).

Depending on the degree of stretching, the rainbow effect may be diminished. We therefore advise you to conduct preliminary trials. The recommended forming temperature is between 290 to 320 °F.

Flame Polishing

ACRYLITE Reflections iridescent sheet can be flame-polished under the same conditions as standard acrylic sheet. For best results, flame- polish stacked sheet. The coated surfaces should face inwards, to protect them from the flame.

If you would like to flame-polish individual ACRYLITE Reflections iridescent sheets, we recommend placing the sheet with the coated surface on a sheet of standard acrylic for better protection.